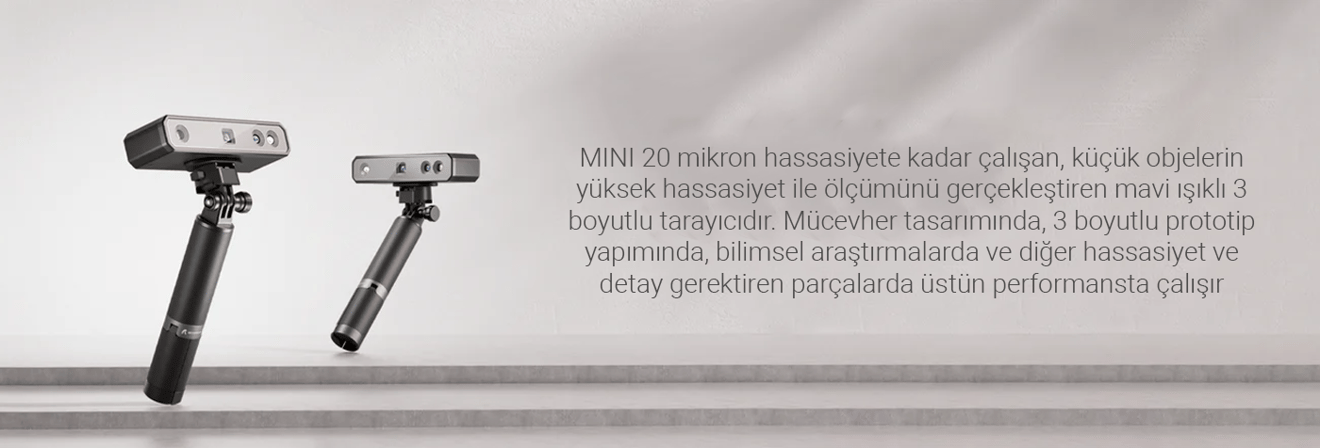

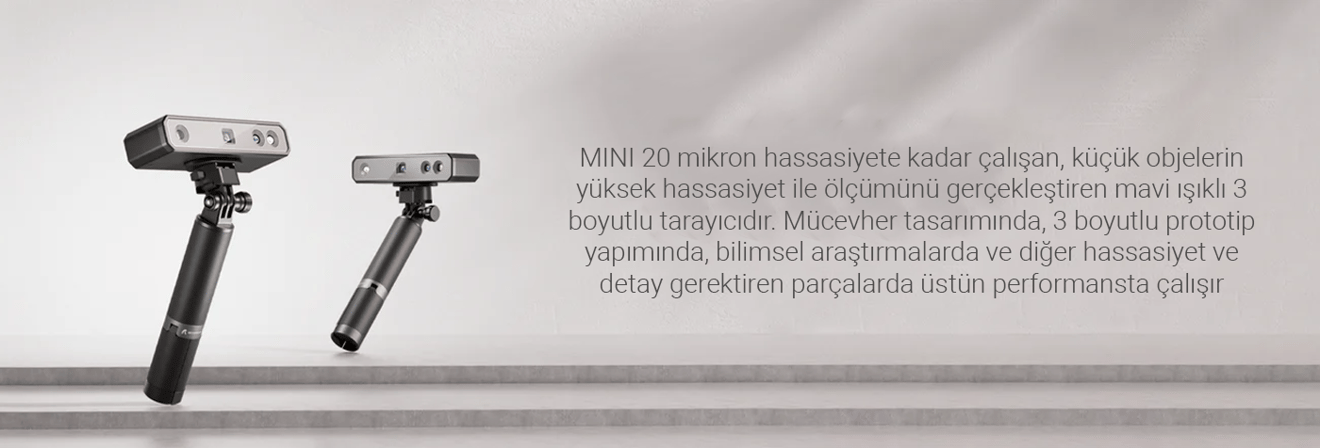

Revopoint MINI 3D Scanner

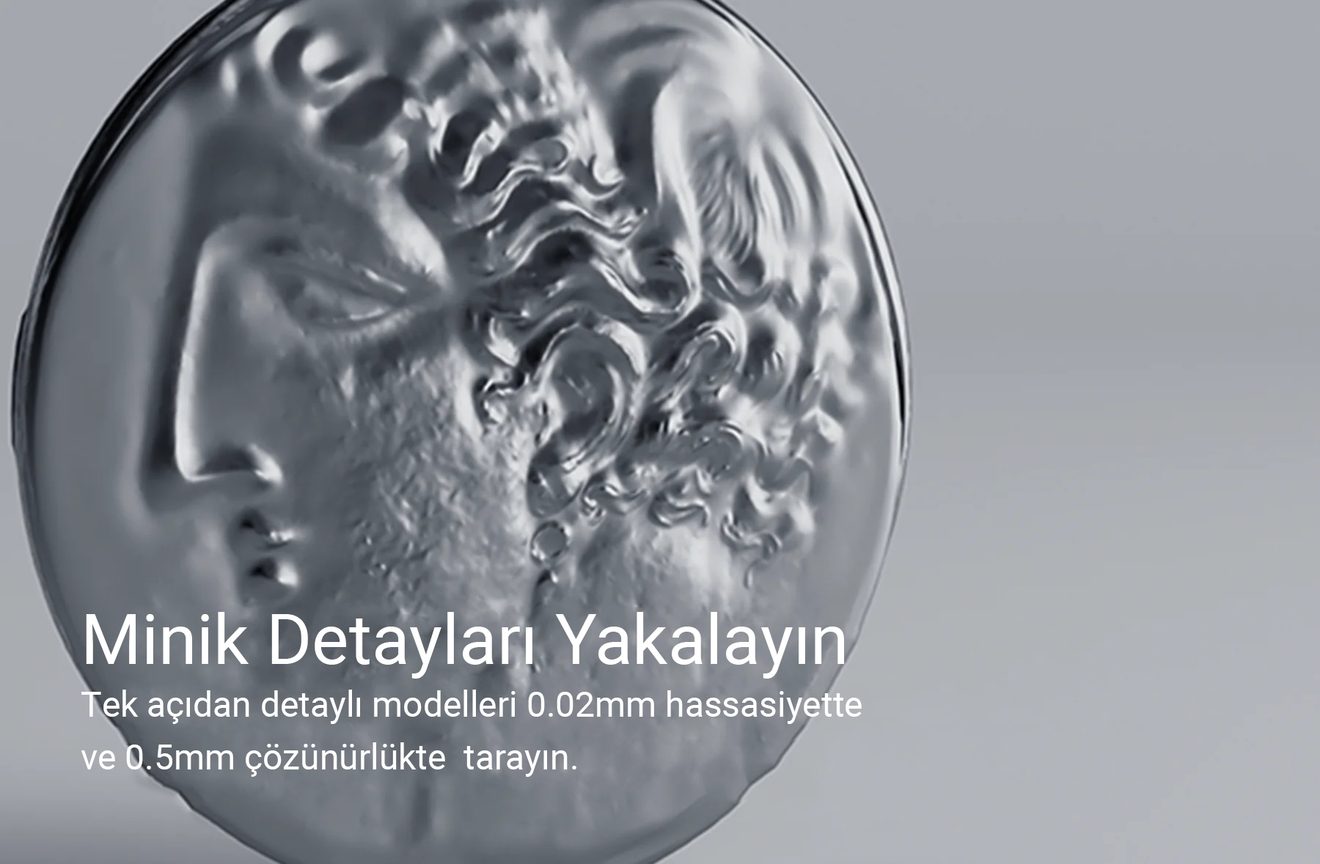

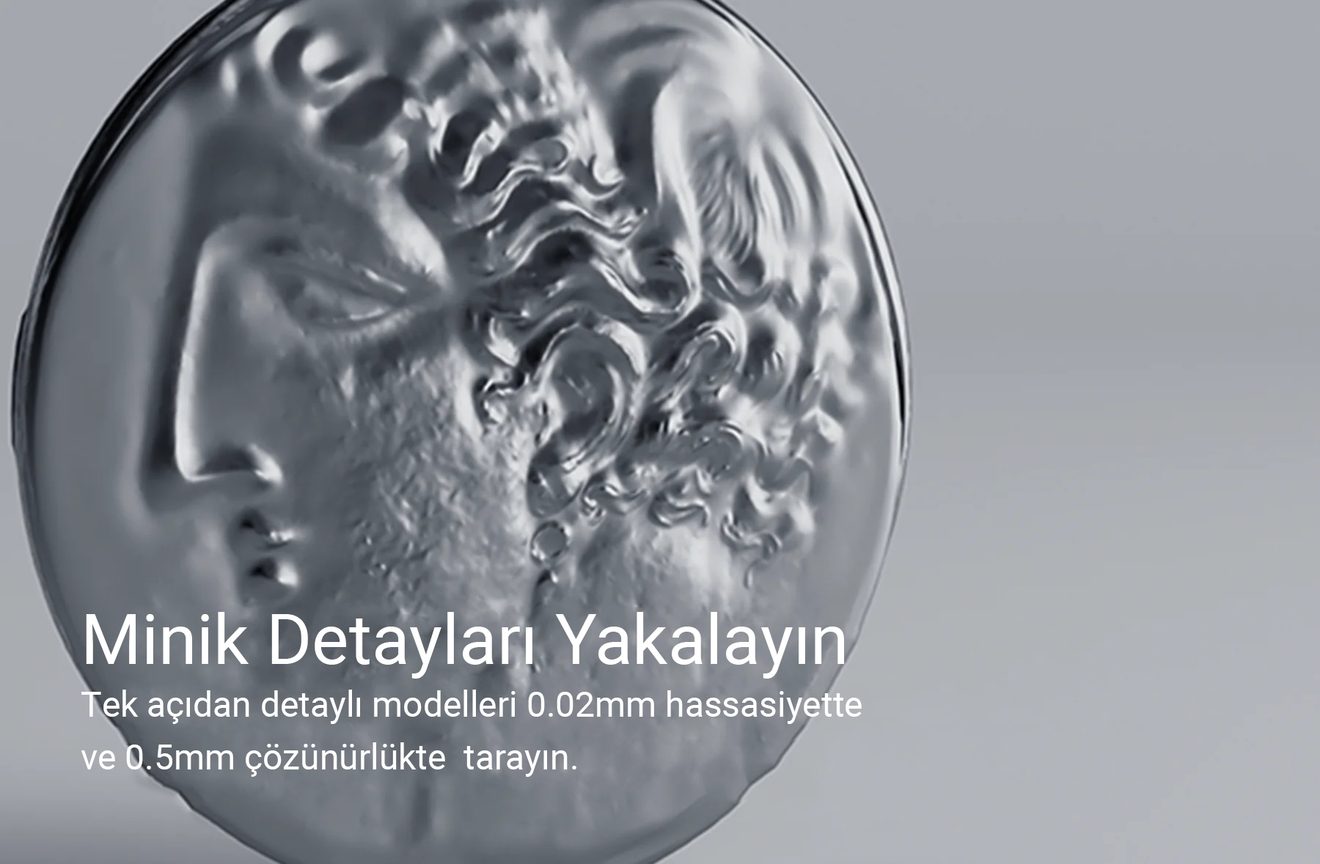

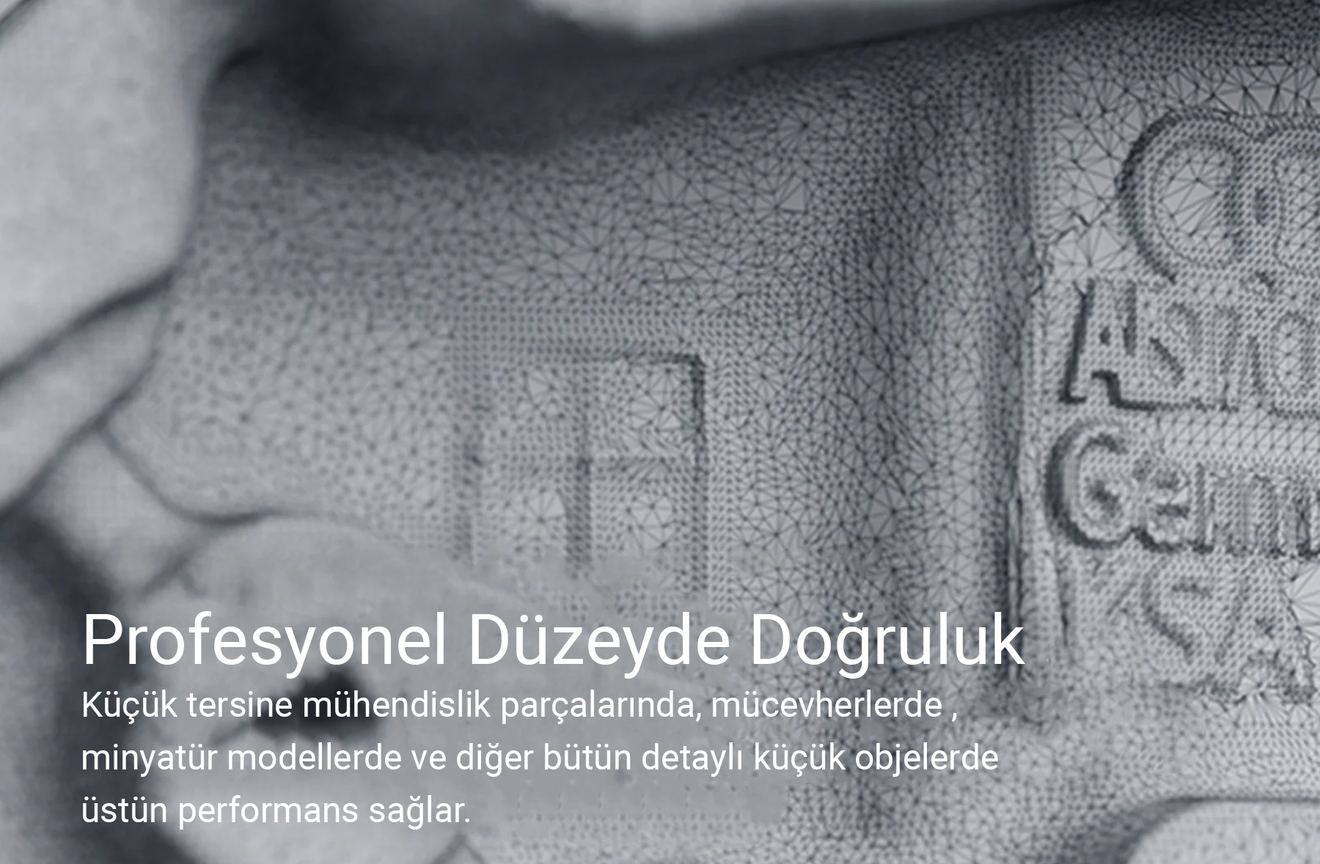

Incredible Precision of 0.02mm

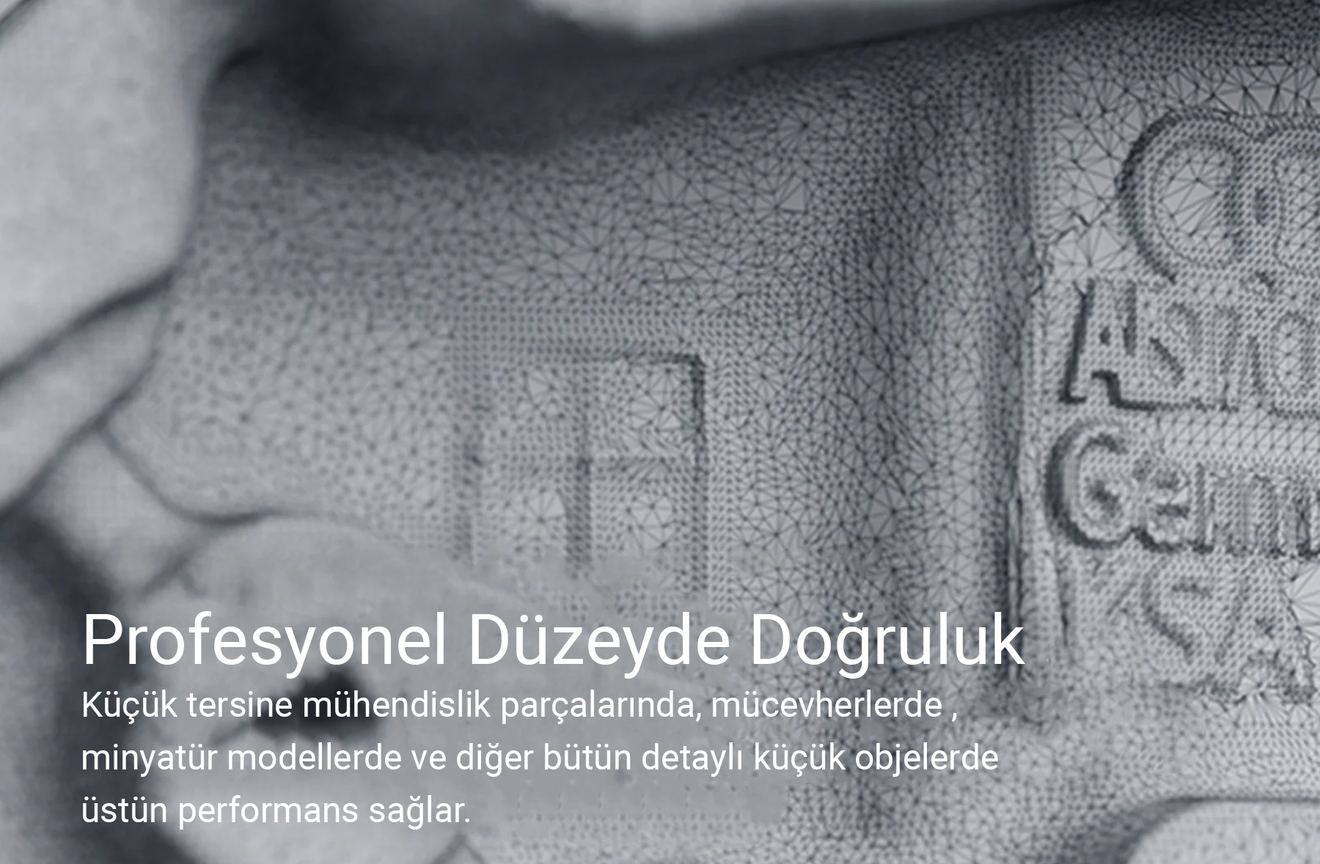

MINI's industrial-grade scanner sensitivity of 0.02 mm ensures that even the smallest parts are accurately scanned and presented. The output model has a high density of point clouds with a point distance of 0.05 mm. You can use the MINI for dental mold making, jewelry design, garage kit reproduction, miniature 3D model making and other fields and situations where detailed high-precision models are required to be achieved.

Industrial Blue Light

MINI adopts industrial-grade blue light technology, which reflects ultra-high-definition structured light and has strong resistance to ambient light. The blue light used in the MINI scanner is harmless to the human body and can be scanned directly on the skin, making it safe and user-friendly for all possible applications.

Scanning Speed up to 10fps

Revopoint MINI has a scanning speed of up to 10 frames per second. With the help of improved intelligent algorithms, it can significantly reduce stitching errors in sequential scanning. Integration of a proprietary chip enables MINI to directly output 3D data. Scanning Speed up to 10fps

Revopoint MINI has a scanning speed of up to 10 frames per second. With the help of improved intelligent algorithms, it can significantly reduce stitching errors in sequential scanning. The integration of a proprietary chip enables MINI to directly output 3D data.

Easy to Use Software

To achieve an even more perfect model, Revopoint has developed three powerful software: 3D scanning software Revo Scan, professional model editing software Revo Studio and calibration software Revo Calibration. Each of these software can be used at different stages of the scanning process to help create a high-precision 3D scan that captures every detail the user wishes to include.

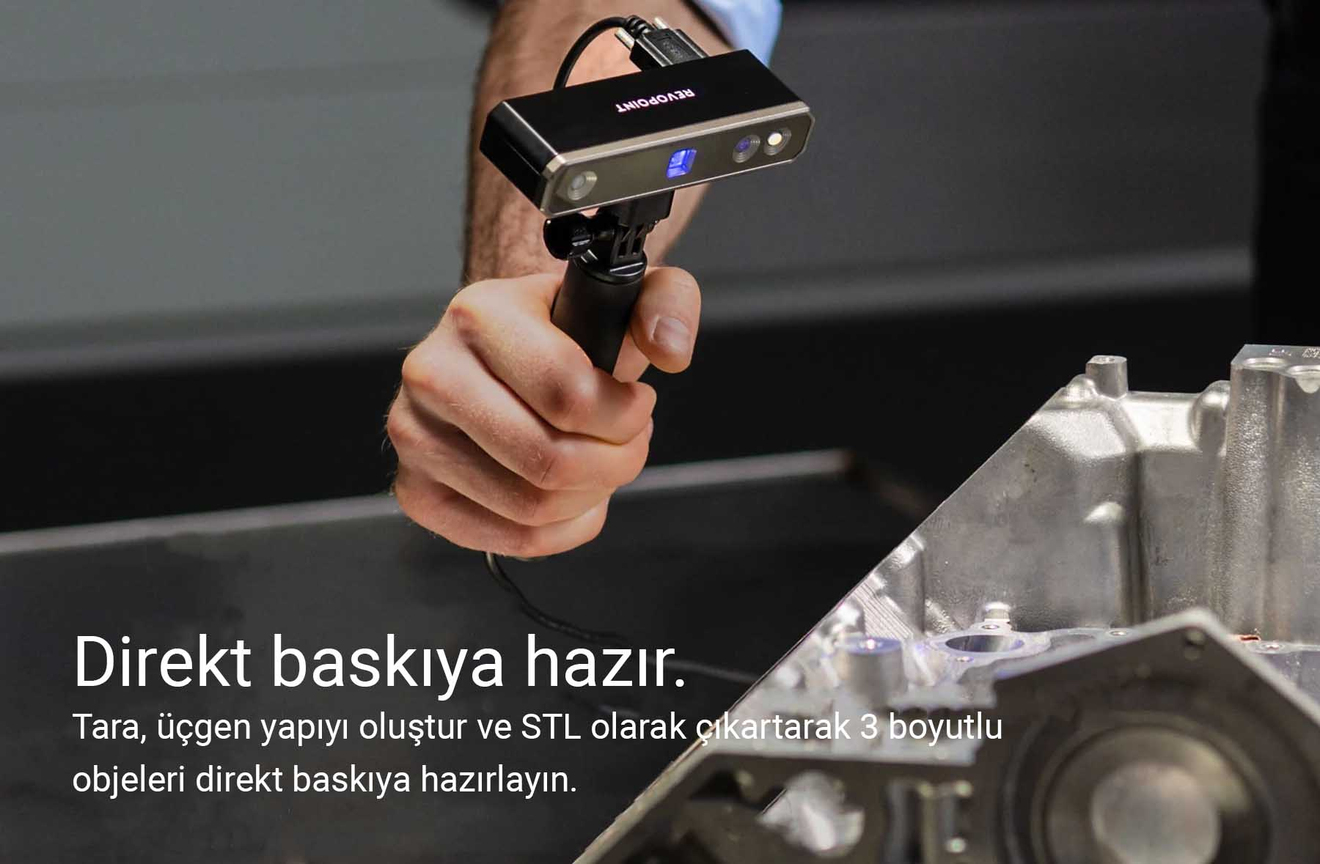

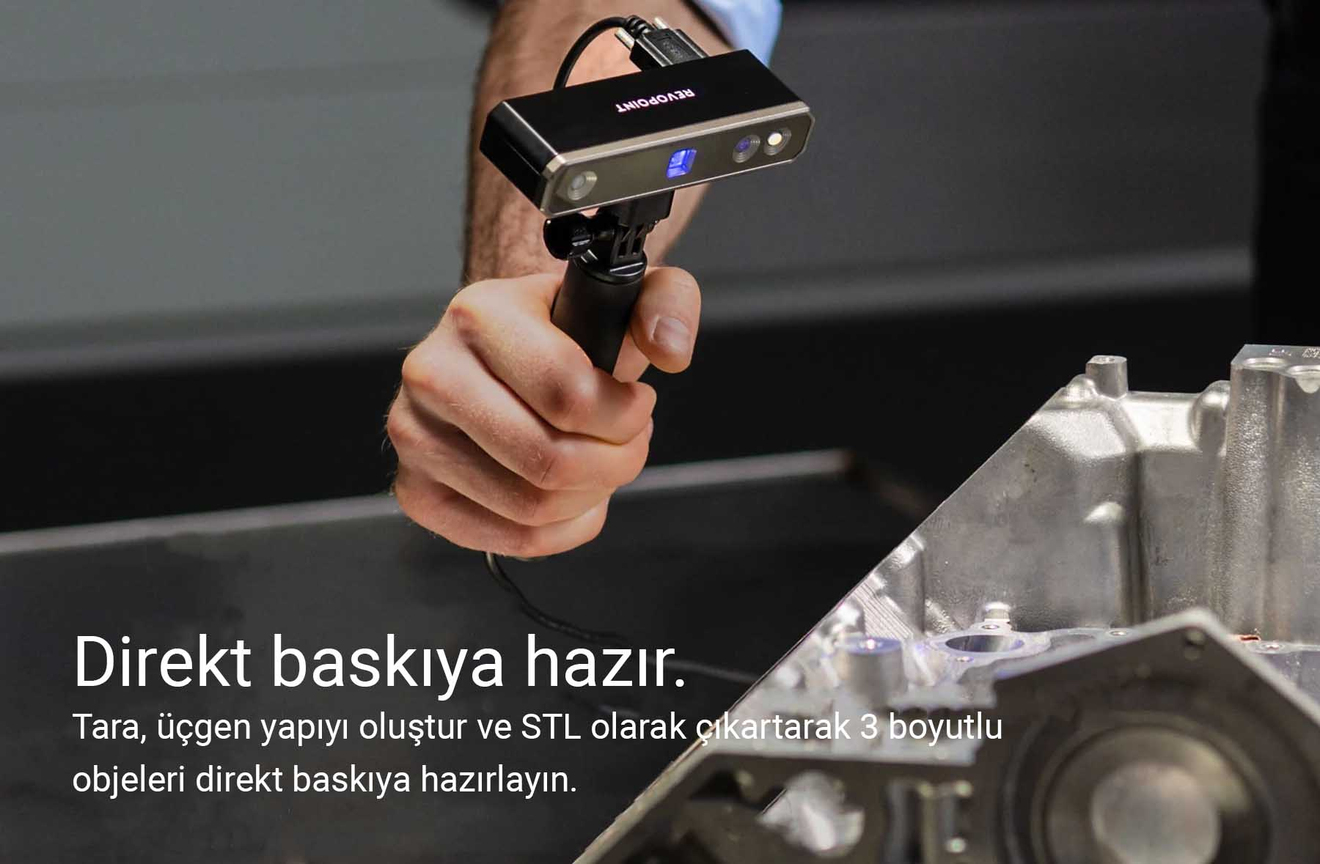

Compatible with Design Software

Model formats output by Revopoint scanners are compatible with mainstream 3D rendering software. Ideal for users to achieve a convenient and efficient cross-platform workflow

A Wide Range of Applications

MINI is widely used in reverse engineering, digital processing of fossils and cultural relics, jewelry design, medical application, 3D animation, quality inspection, etc. It can host many applications including.

Advanced Package Accessories

Handheld Stabilizer

The S1 Handheld Stabilizer is designed for the Revopoint 3D scanner series, including the POP and MINI series. It is equipped with a built-in high-precision gyroscope and stabilization device. It can effectively eliminate poor point cloud sensitivity and monitor image losses. This ensures smooth scanning without stopping.

Double Axis Rotary Table

The dual-axis rotary table A230 is an accessory made specifically for Revopoint scanners. It features a 360° horizontal design, approximately 30° vertical angle and a controlled rotation path for fast point cloud data collection. It greatly improves scanning quality and efficiency by solving previous problems of incomplete data collection or holes caused by incorrect operations such as media clogging.

Detachable Tripod and Quick Installation Kits

Using kits to adjust your scanner to the appropriate height and angle allows you to scan more comfortably. It features free expansion and height adjustment for expanded device compatibility and to accommodate multiple applications.

Scanning Spray

AESUB is a globally recognized scanning spray solution provider. The purpose of a scanning spray is to create a non-reflective surface on objects while scanning to increase efficiency during scans. It works by providing a thin, homogeneous coating and disappears on its own within 4 hours, meaning there is no need for post-combing cleaning. AESUB blue series does not contain pigments or damage sensitive scanning equipment, laboratories or production sites.